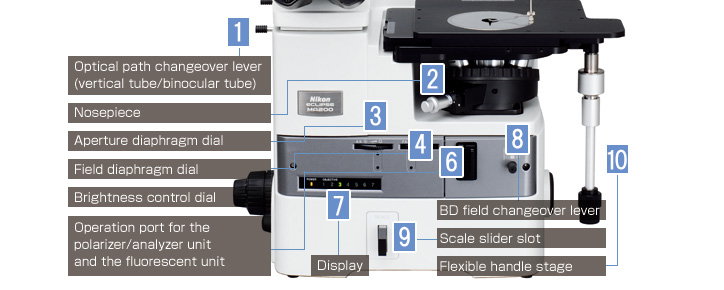

ECLIPSE MA200

Nikon's very own solution for an ideal microscope

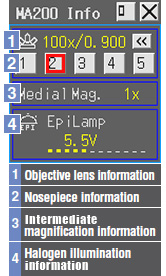

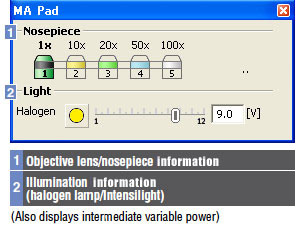

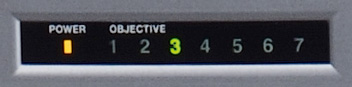

Automatically detects the address of the objective lens currently in use and displays it on the main unit front panel.

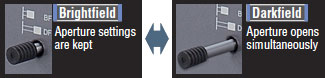

Brightfield

DIC

Brightfield

Simple Polarizing