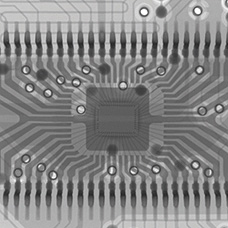

Compact, versatile and easy-to-use electronics QA system

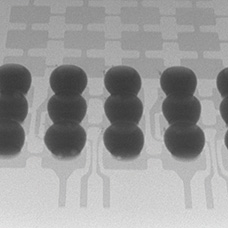

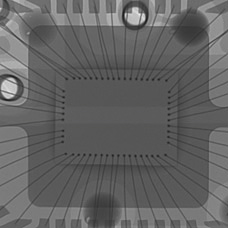

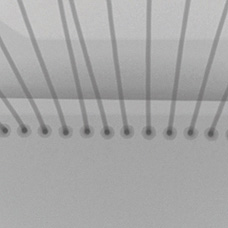

The XT V 130C is a highly flexible and costeffective electronics and semiconductor inspection system. The system features a 130 kV/10 watt Nikon Metrology manufactured source, a globally recognized open tube design with integrated generator, and a high-resolution imaging chain.

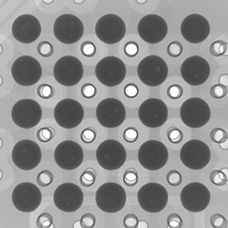

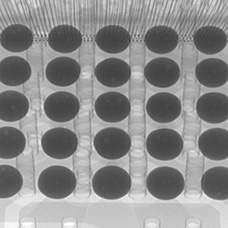

Superb image magnification enables users to zoom in on any specific item of interest