Enter the world of X-ray CT

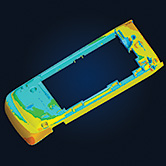

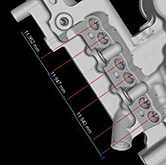

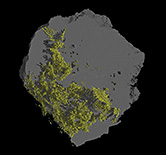

Detailed capture and measurement of internal component and assembly features is often vital for quality control, failure analysis and material research. XT H 225 offers a powerful micro-focus X-ray source, a large inspection volume, and high X-ray and CT imaging resolution. XT H 225 suits a wide range of applications, including inspection of small castings, plastic parts as well as material research.

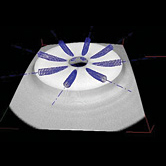

XT H 225 ST 2x microfocus X-ray CT system allows a doubling of data acquisition speed and hence of inspection productivity. It is a result of using advanced detector technology combined with new funtionality.

XT H 225 ST 2x microfocus X-ray CT system allows a doubling of data acquisition speed and hence of inspection productivity. It is a result of using advanced detector technology combined with new funtionality.