Top-class inspection system for miniaturized electronic components

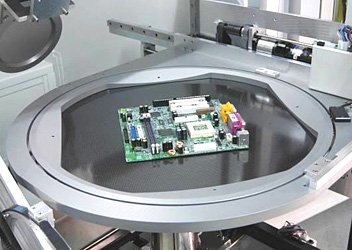

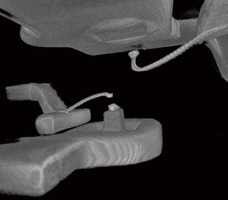

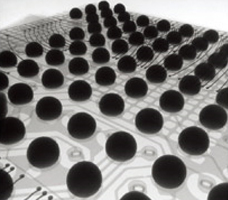

Component connections on today’s compact and densely populated PCBs are hidden by other components, making X-ray the only viable inspection solution. XT V 160 is an easy-to-use, cost-effective and high-quality PCB inspection system targeting production facilities and failure analysis laboratories.

In automated inspection mode, samples can be inspected at the highest throughput. In manual mode, intuitive software and high-precision sample manipulation enable operators to visualize and evaluate the tiniest internal defects and deficiencies.

In automated inspection mode, samples can be inspected at the highest throughput. In manual mode, intuitive software and high-precision sample manipulation enable operators to visualize and evaluate the tiniest internal defects and deficiencies.