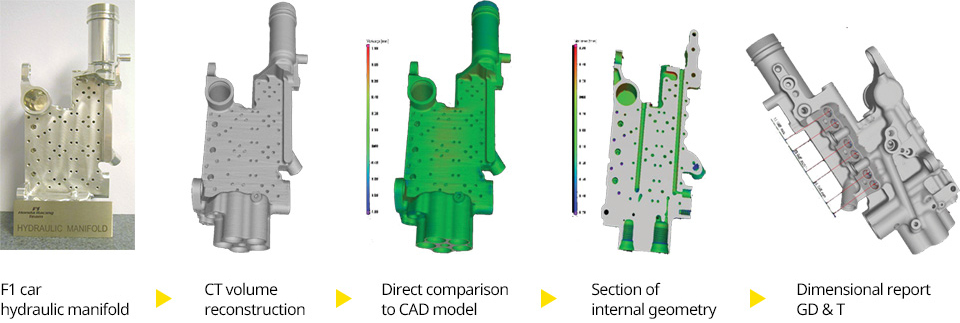

MCT225 offering absolute accuracy for inside geometry

MCT225 efficiently measures internal and external geometry without reference measurements and damaging the sample. With fifty years’ CMM experience and twenty five years’ X-ray experience, our pedigree for reliable high quality Metrology CT is second to none.